“We’ve always done it this way.”

Does that sound familiar? It shouldn’t, but you’ve probably heard it a lot anyway. Once a process is implemented, teams often neglect to review it from time to time. Process improvement is powerful but underused.

The reasons can be multilayered:

- Teams don’t have time to review the processes.

- Responsibilities within a team are unclear.

- Teams don’t know how to review processes.

- Teams don’t know how to implement changes.

Of course, I can’t provide you with more time or capacities. I‘m also unable to set your internal responsibilities. But I can show you how you can easily improve your processes, and I can provide you with interesting real-life examples.

Before we dive into the topic, let’s make sure that we’re on the same page. What’s process improvement?

The Definition of Process Improvement

Process improvement refers to the effort that goes into choosing, understanding, analyzing, re-designing, implementing, and monitoring the processes you want to improve.

The goals of process improvement can be different, but the overall goals typically involve saving time or costs. In addition, improving a process can lead to increased employee satisfaction and productivity.

For example, your coworker Zach needs to transfer data from a printed form to a spreadsheet. This process keeps him away from other more meaningful tasks. A better solution could be to let customers submit an online form, and automatically transfer the data. After digitizing this process, Zach will both save time and be more motivated, since he doesn’t need to spend time on cumbersome data entry anymore.

Process improvement doesn’t need to be intuitively performed. (And it shouldn’t be). Several tools and frameworks (such as Kaizen, 5S, and hypothesis testing) can help you improve your processes. Some of these tools were developed for manufacturing companies, but most of them can also be used by all sorts of firms.

Lean Process Improvement

Process improvement isn’t a one-time task. It needs to be continuously performed, which is how the lean approach comes into play.

James P. Womack, Daniel T. Jones, und Daniel Roos first coined the phrase “lean approach” in their book about the Toyota production system. While designed to improve the production of cars, this approach can also be applied to many other businesses.

In order to be effective, the lean approach needs to involve an organizational mindset. It requires aligning all departments and ensuring that each division is willing to regularly improve processes.

The goals of lean process improvement are:

- minimizing waste

- optimizing time savings on a daily basis

- and systematically improving the value provided to the customer.

This ongoing process will help a business iteratively improve their results.

The typical loop for lean process improvement looks like this:

- You define the value from a customer perspective.

- You visualize the process and pinpoint the steps that aren’t adding value.

- If these steps can be changed to add value, change them. If not, remove them.

Process Improvement Plan

1. Understanding and Mapping the Process

After choosing the process you want to improve, you should concentrate on fully understanding the process and its sub-processes. Afterwards, you should visually depict the process in its full complexity. It’s crucial that you don’t leave out any steps of the process.

If you’re unsure about specific sub-processes, talk to the people involved. They’ll be able to explain the steps in detail. Also make sure that you’re clear about the business goals and the potential impact of the improvement process.

Ask yourself:

- What do you want to achieve?

- If you improved the process, how would it affect your individual performance and your team’s performance? And how would it affect your savings (both time and costs)?

- What resources do you need to improve the process?

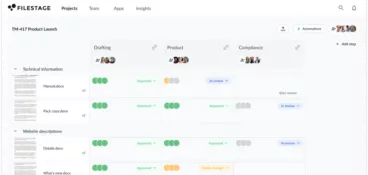

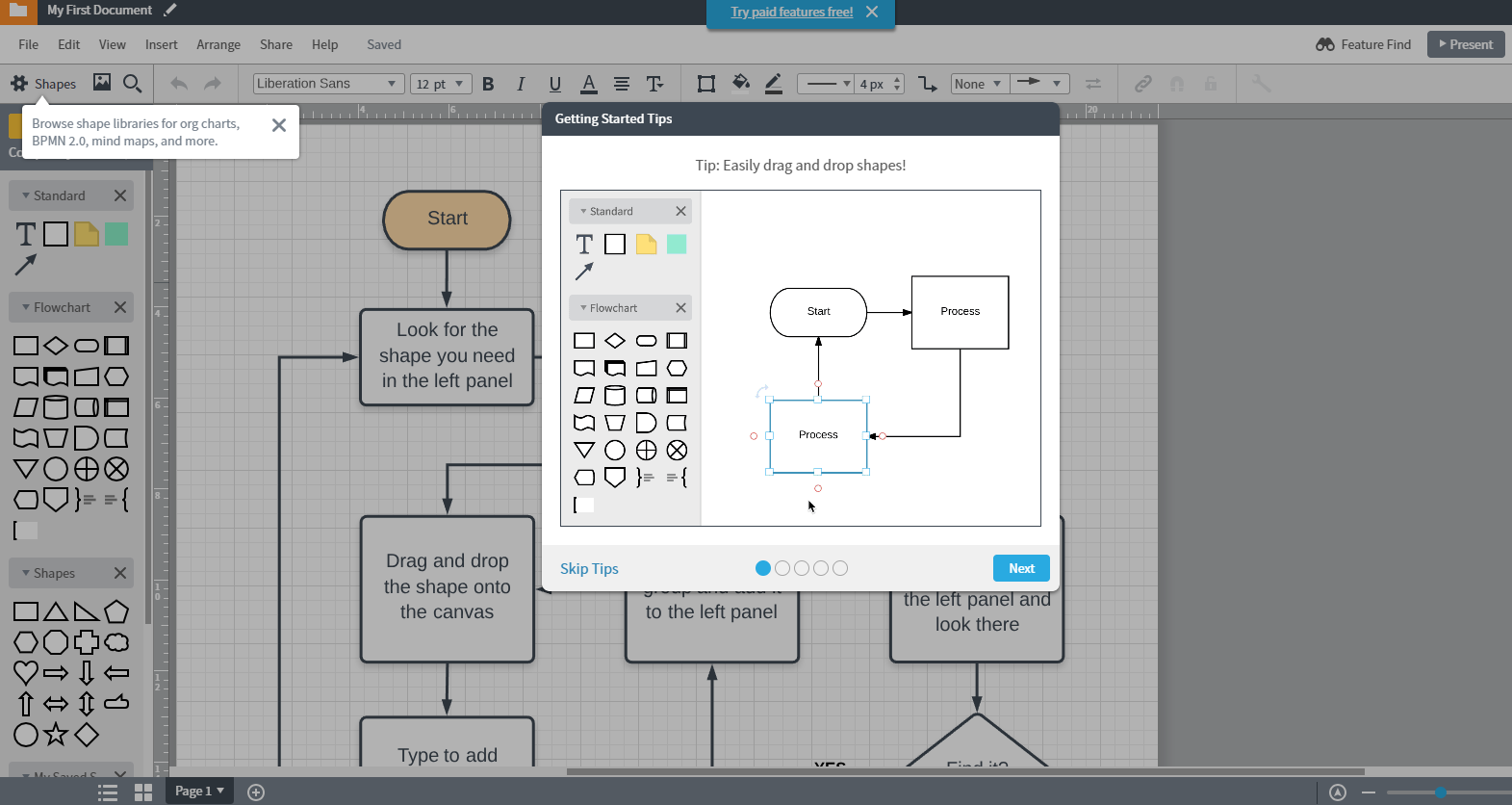

To map the process, you can use a tool like Lucidcharts or Visio. That way, you’ll be able to share the process map with your coworkers as needed. Of course, you can start depicting the process by using pen and paper, but doing it online will help you involve other people and simplify the collaboration process that’s involved.

Process Improvement Tool Tips:

2. Analyzing the Process

After mapping the process, you should focus on finding potential problems and issues. Hence, you need to start analyzing your visualized processes, in order to discover bottlenecks and conflicts.

During your investigative process, ask these questions:

- Does one of the steps in the process result in bottlenecking?

- Which new steps are harming the overall performance? Would it be better to keep these steps as they are?

- Are any of the steps obsolete? If you removed one of them, would the result stay (more or less) the same?

- Which steps have the highest impact on the final result? Is it possible to simplify or optimize them?

- Does the process include steps that generate frustration?

- Do any of the new steps take more time than the old steps?

- Which steps cause delays? Is there a way to optimize these steps?

- Which steps result in the most costs? Can they be optimized?

While investigating, it’s important to detect the root of the problem. It’s useless to fight the symptoms of a problem without fixing the cause.

Process Improvement Tool Tips:

3. Optimizing the Process

You’ve found the problem and its cause? Perfect. Now you can start optimizing and adjusting the process. Obviously, I can’t provide you with a holy grail that will optimize your process without knowing what the process is. Nevertheless, I can equip you with some general advice and tools.

Your optimization effort needs to follow the KLIRRI approach. What does that crazy acronym stand for?

Key Performance Indicators

You’ll only be able to compare the situation— before and after optimizing the process—if you decide on suitable KPIs. Set the metrics, and start monitoring them on a regular basis.

Long-Term Goals

Some process improvements might result in short-term benefits, but they won’t pay off in the long run. Make sure that you’ve defined the long-term goals, including ways to achieve them by improving your process.

Involve People

You can only optimize a process if you know all the details. Make sure that you’re involving the people who are using these processes on a daily basis. By bringing them aboard, you’ll benefit from their knowledge and their reasons for wanting to improve their situations.

Risk Assessment

Calculate the risks wisely. You’re estimating an impact, but you can’t be sure that it will be totally accurate. Hence, allow for all reasonable possibilities, and prepare yourself for surprises. You can consider using risk assessment software that helps you dramatically reduce the likelihood of any occuring risks.

Resource Management

A lot of processes could be improved if the needed resources would be available. Make sure that you know about the capacities that are needed to improve the process. If you know what it takes to conduct the changes, calculate whether if the long-term impact is worth the effort. Resources can include people, money, software, pens, and coffee etc. Create a list that includes all needed resources, and make it as detailed as possible.

Impact Analysis

What are you expecting from the process improvement? How will the results affect your overall goals? Make sure that you know which direction you’re heading in. And use metrics to measure this impact.

What does the optimization process look like?

- You and your team identify the problem(s) in a process.

- You generate ideas as a team, in order to overcome the hurdle.

- Your team prioritizes ideas, based on:

- The potential impact of the solution.

- The resources that are needed to implement the solution.

- The potential risks that go hand-in-hand with the solution.

- You agree on one or more ideas.

- You and your team make sure that the idea is applicable and decide on the action steps that are needed.

Process Improvement Tool Tips:

Brainstorming

Failure Mode and Effects Analysis

4. Implementing the Process Improvement

Now you’ve defined the optimization process, and come up with some actionable steps. Great! Let’s put the plan into practice. This part of the process is crucial, and it will decide the success or failure of your plan.

Keep in mind that implementing the new process can become its own project, and should be planned in detail. Make sure that you have access to the necessary resources, and that your team and your entire organization are onboard.

Often, you need to convince some people that your process improvement will make a difference and that it’s worth the effort. Hence, this step is also about mastering the organizational politics.

A lean implementation process could look like this:

- Start testing your hypotheses by implementing the improvements on a small scale.

- Tweak your strategy as needed.

- If your plan works on a small scale, try it on a larger scale by communicating changes with important stakeholders.

- Implement the process improvements.

Tools for Process Improvement:

Kubler-Ross Change Curve

Kotter’s 8-Step Change Model

Force Field Analysis by Kurt Lewin

5. Reviewing and Monitoring the Process

After rolling out the new process, you need to start actively monitoring this process. Often, the changes won’t work when you first try them out. This initial outcome is normal and shouldn’t scare you.

Keep in mind that process improvement is a continuous process. If a new problem appears, attend to it, and make sure that it’s fixed. Create a spreadsheet, and monitor the important KPIs you’ve already defined on a weekly basis.

Process Improvement Examples

#1 Reduced Turnaround Time

We try to always keep an eye on our processes. At least once a year I take

a day to go through the business thinking about ways to make it more

efficient. Leading up to that day I ask our team for feedback, things

they’re struggling with, improvements they might suggest, etc. I try to get

the entire picture.

A recent example we did earlier this year was with our inquiry process. New

warm leads that reach out to us about our service. We’re a blog writing

service and to start we offer a free trial first post. I was looking into

the success rate with those free trials and identified that from the day

the person reaches out to us it takes 5-7 business days for them to get the

post. I wanted to see if we could reduce that.

We did a few things, but a big one was we asked a few writers what

turnaround would work for them for getting a title and notes and writing

the blog post. They told us 2-3 days is very reasonable. We had assumed 4-5

and that timeline had stuck as sometimes happens.

So we shortened that and it’s been fine and it’s helped our success rate.

The client gets to see the post much sooner.

Dayne Shuda, Founder of Ghost Blog Writers

#2 Using Livechat to Qualify Leads

Up until very recently, our sales process was very long and complicated – our customers typically want to customize their items, and every customer wants something different.

Our sales team were usually spending over 30 minutes on each call with customers, which was a drain on our resource.

We introduced live chat on our site to streamline the process and figure out what the customer wanted before we got them on the call.

This has helped reduce the average call time to less than 10 minutes.

Max Robinson, FishTankBank

#3 Custom Software For Streamlining Your Operations

As a company, we’ve made big strides in improving our processes this past year. We are lucky to have a software developer on staff that is able to build custom software to help streamline our operations.

Step 1: Team Conversation

The first thing we did was sit down with our operations team and our software developer. We had the operations team list all the things they do on a day-to-day basis that take up a lot of time.

This was honestly the hardest step. Whenever you’re improving processes, employees often see this as a software developer taking away their work through automation. And to some extent this is true. Luckily in our case, we have a lot of work to go around, and we’re hoping to take away mundane processes so that our employees can focus on activities that help us grow our company.

It’s very important that you communicate to your employees that their jobs are not being automated away and that they are essential to the growth and success of your company in the future.

Step 2: Automating

After we wrote down a long list, we discussed with the software developer strategies for automating various tasks. We prioritized automation based on the amount of time the activity takes up for our operations team, along with the ease of automation.

There are some activities we decided we just shouldn’t automate away, like interacting with our customers over phone and email. Other activities, like sending weekly classroom reports about student progress to parents, we were able to automate.

Step 3: Iterative Improvements

You should never expect your automated solution to work perfectly right off the bat. There’s a period of trial and error over the next several weeks where things that you never expected to happen will happen and your software developer will make improvements to the automated processes to continue to refine the business logic. I always tell my team things will get harder before they get better – but they always get better!

Improving business processes is critical for our team because we want to expand our computer science education programs to new cities in the next year.

Lindsey Handley, COO at ThoughtSTEM

#4 Improved Communication Workflow

Problem

We run a multi-office consulting service in 3 equally spaced time zones around the world to expedite architecture, engineering, construction and building operations. This process is overseen by US-based engineers around the clock. Part of the challenge of operating BIM Theory is communicating expectations over technical language barriers, time differentials, and cultural discrepancies. As we got started we soon observed a high rate of issues resulting in re-work and missed deadlines. A problem truly at the intersection of People, Process & Technology.

Process

Phase I: Baseline.

The first step of any process improvement is providing a measurable baseline to build upon. We sat down and discussed possible measures ranging from general to extremely specific. This is where most people get hung up because they want to seek out perfect data to flawlessly represent what is happening.

The secret is to choose the simplest measure that requires the lowest cost and least participation & monitoring. We chose to simply measure instances of miscommunication rather than trying to measure actual hours vs expected hours. Once we had a statistically significant baseline, it was time to move on to Phase II.

Phase II: Trial improvements

When it comes to brainstorming improvements we like to sit at a roundtable where everyone feels open to express their opinion and debate it freely. One of the rules we have is that you should remain free of path dependence and therefore have an open mind to other’s ideas.

We came up with several trial ideas:

- Implement a text & task-based project management web app with clearly defined process templates.

- Create videos that clearly communicate daily tasks with markups, clicks, and keystrokes shown.

- Host a 15-30 minute video conference discussion during the turnover period between time zones.

Phase III: Deployment

We deployed all three improvements evenly over our different business lines and gave it a 2-week break in period to allow for the team members to get acclimatized to the new process before starting measurement.

Measuring versus our baseline we found that the video conferences were most successful but also ran into the most technical issues with timing and connectivity. Luckily, the next best performing option was the video instructions which didn’t suffer from those issues.

In the end, over 6 months we were able to eliminate 50% of communication mistakes causing rework which amounts to a substantial gain. We’ll continue to iterate on this process.

Nate Efron, Founder BIM Theory

#5 Custom-Built Tool Saves 5 Hours a Day

My business runs marketing campaigns using influencers. For the longest time, I was the one that collected performance analytics after a campaign had ended. This meant going to each individual post, looking at the engagements, and entering them into a google spreadsheet and generating a report. All in all, it was about 5 hours of incredibly boring work a day.

Once I knew the process like the back of my hand, I contacted a local software developer and explained step by step what the process included.

He sent me a contract that stated it would take him 10 hours and cost me $1,000 to make it 99.99% automated (I still had to log in to the tool and press a button). I paid the invoice and two weeks later had a tool that took me 5 hours of work and turned it into 5 minutes. Literally.

Since then, I’ve had a handful of other workflow management tools made that make my job a million times more efficient. Tim Ferriss would be proud ;)

Morgan King, Founder at Market Boost

#6 Optimizing the Recruiting and Admissions Process

As a former management consultant focused on project management I’m always looking to improve processes.

Since arriving at Gordon College in September I’ve done just that. One example is reviewing the recruiting and admissions process.

The goal is to streamline, standardize and automate. Such as removing the paper application option and moving to electronic only. Or eliminating stages in the process, automating responses and having less hands which need to touch the application.

Moving to self-service by the applicants has freed up internal staff to focus on more client-facing, external work.

Alexander Lowry, Professor of Finance at Gordon College & Director for the School’s Master of Science in Financial Analysis program

#7 Implementing a New CRM in 3 Months

With our organization’s continuous growth and success, our old IT systems and processes needed scaling, as well as the ability to grow as we grow. This meant implementing a new CRM, which is a gigantic undertaking for any organisation.

Our IT team had to be able to work with speed and acute attention to detail on a local and global level. We worked with partners and niche consultants and created a process which allowed us to migrate CRMs in just over three months.

IT is often viewed as the framework or structure of a business. For us, IT is using the latest technologies to help streamline our business processes and performance which means we can work more efficiently, more effectively, and smarter. Ultimately, this allows us to better focus on the needs of our customers.

Matthew Anderson, IT Development and Applications Director at Pearson Frank

#8 Workshops that Helped to Identify What Provides Value (and What Not)

Several years ago, I was a senior manager in a finance organization. All of my peers were responsible for accounting operations and my team managed the applications. Every few years our boss would ask us to review the operations. The trigger for these reviews was usually excess overtime during the monthly financial close process.

I would facilitate a several day workshop with my peers. The first thing we would do was identify what provided “value”. In our case, we would look at the value of the revenue booked through each of these processes versus the relative level of effort expended. Each of the managers would first identify the monthly revenue stream and the number of staff hours expended to report that revenue.

This analysis gave us a quick view of where we had mismatches in effort and value. For example, an old product that brought in less than $1000K/month in revenue required more effort that one billing over $100M/month. So, we knew we had to do something about the effort on the old product because it was clearly not worth the effort.

We would then do a value-stream mapping exercise. We would start with a high-level view of the value stream. We would ask ourselves does the process make sense before diving into the details. In the example of the old product that did not bill much, we decided to completely revamp the process. Rather than focusing on trying to estimate the entire month’s revenue, we would estimate the first month and then true-up in the second month.

For other value-steams, we would go through the process in detail and ask pointed questions:

Did the step add value?

- Was our level of precision appropriate?

- Did we have too many control and approval points?

- What would be the impact of estimating more?

All of these questions were helpful in prying people away from their beloved processes. At the end of the workshops, we typically identified and implemented process changes that resulted in 25% effort savings. That was a lot. It meant that people were leaving work on time during the close instead of staying until 10PM or later.

Alan Zucker, Founding Principal Project Management Essentials

#9 Optimizing the Promotion Process for New Events

Here’s our general strategy:

- Identify something we do repeatedly

- Break it down into smaller steps

- Document those steps

- Hand off the documentation to another person to try independently

- Automate any components that are possible

- Repeat steps 2-5 as needed

One process that goes on at our firm is promoting upcoming events. At first, this was done on an ad-hoc basis. We’d sometimes remember to put details on our website in the form of a new blog post, and other times we’d add something to our email newsletter.

Then, we decided to hand off the task to someone else. It was clear that we’d left out a bunch of details, such as ensuring that the event announcements had clear registration details, that they mentioned any sponsors, and that we had bios of the speakers.

Eventually, we moved to a dedicated site plugin for managing events. And then we realized that we could customize the plugins to have a dropdown of common event types and all of our presenters to pre-populate them with bios.

Once that worked, we got an automated tool to pull any upcoming events and place them into our email newsletter. And we also established a pattern from promoting events on Twitter.

Now, the event announcement process is almost entirely seamless. We pass along the details to the person responsible, and they take care of everything using a checklist and existing tools. And when we find something that needs improvement, we fix it!

Robby Slaughter, Principal AccelaWork

#10 From a Spreadsheet to a Self-Service Portal

If having a career in DevOps has taught me anything, it’s that communication between teams is paramount. By communicating openly and objectively about existing processes, my teams have been able to identify processes that are prohibiting value-add based departments from focusing on what they do best.

As an example, I once worked for a software company that had a consulting team that was responsible for manually installing the company’s product on their customer’s servers. Once the time-costly and error-prone installation was complete, they manually entered a bunch of information the customer provided in a spreadsheet, to configure their system. Another team that was upstream in the onboarding process was also responsible for validating the information that was provided in the spreadsheet with the customer. Naturally, there would frequently be back and forth communication about what information is being requested.

Since the Consulting team was a revenue-generating department, our team decided it would be best to coordinate some meetings to figure out how we could improve the process. The process I mentioned involved many other departments, so it was critical that we speak with stakeholders from each to get their buy-in.

During the initial project kick-off meeting, we proposed digitizing the Excel spreadsheet via an online webform and that we automate the installation and personalization of their system. Throughout the following weeks, teams did more digging and communicating with their team to see how what we were envisioning for a new process would fit into their routines.

Rather than taking a high-risk approach, we employed canary testing by implementing the new process in parallel with the existing one. Doing this is highly beneficial for customer-facing processes so that you’re able to quickly learn and refine the proposed process.

In the end, we all worked together to create something that would benefit all departments involved in the process. This enabled each department to spend more time thinking about how they can improve other processes of their own. It might not be blatantly apparent, but refactoring processes a bit can yield recursive improvements.

Departments and managers can spend less time doing and more thinking about what’s working and what isn’t. If it’s a customer-facing department, maybe the team is able to spend more time walking your customers through other processes, yielding a great customer experience for your product.

For us, the new web form process walked customers through all of the technical product details and answered a vast majority of the frequently asked questions. It truly became a self-service portal, and the customers loved it!

Marcus Bastian, Owner at Clouductivity

#11 Small Loop Fixes

One of the biggest process improvements we made was to institute what we call “Small Loop Fixes” (otherwise known as the Build-Measure-Learn cycle) as a 2018 yearly goal. So far, we’ve seen the greatest impact in our automated drip emails.

Our drip emails help nurture contacts over several months by sending them relevant information about Smartleaf’s capabilities and tailoring the messages depending on their responses.

In 2017, we sent over 32,000 emails in 8 different workflows that helped to nurture several thousand prospects. It was successful in terms of greatly increasing our touches, but our prospect conversion rates didn’t meet expectations. In 2017, our process for a two-month, five-email long campaign was as follows:

- Write email copy and insert contacts into the drip.

- Review the success of the campaign as a whole after all emails are deployed.

- Adjust the entire campaign to make improvements to copy, targeting, etc.

This year, in 2018, as part of our “Small Loop Fix” goal we updated this process to follow the reoccurring Build-Measure-Learn cycle for the same two-month, five-email long campaign:

- Build: Write email copy and insert contacts into the drip

- Measure: Review the success of the campaign piecemeal, after each email and make immediate changes.

- Learn: As an example, if we notice that email 1 had exceptionally low open rates we’ll update the copy of email 2 to have a different tone that might resonate with the audience better. Once email 2 is executed, we’ll review if open rates have increased, decreased, or remained the same and take appropriate actions. This testing process continues for all aspects of the email at each stage of the drip campaign.

So far, this Build-Measure-Learn cycle (which is one of the tenants of The Lean Startup) has allowed us to be more nimble and action-oriented in all of our marketing and sales projects. Now we can better ensure that work isn’t done that doesn’t need to be, and changes are made as soon as possible. We still have six months to go before we can fully compare results, but so far we’ve sent fewer emails while increasing our conversion rates; we’ve essentially started to work smarter.

Camille Carlton, Head of Marketing at Smartleaf

Conclusion

It’s important to review your processes from time to time. You may have gotten used to an unhealthy process that’s harming your overall performance. If so, you can use the process improvement plan to change this situation.

Are you regularly improving your processes? If yes, what’s your best advice about process improvement? Let me know about it in the comments.